- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 176 Author: Site Editor Publish Time: 2022-09-13 Origin: Site

Food contamination is a well-known topic, and the news media will actively target such safety issues to protect the legitimate rights and interests of consumers. But have you heard of cosmetic pollution? Cosmetics can be said to be the most common chemicals that women come into contact with. They come into contact with skin and mucous membranes. Unqualified cosmetics may bring serious infection and microbiological risks. The most prone to problems in the cosmetics manufacturing process is packaging, because any residue that may be stuck in the machine may cause harm and pollution. In this industry, a clean environment and production equipment, namely the cylinder itself, are essential to stay on the market and avoid possible consumer lawsuits. So how does the cylinder bring benefits to the beauty industry?

Choosing the right cylinder can control the number of products that the machine needs to output each time (that is, the cosmetic capacity), so that the container can be perfectly filled with cosmetics. In order to ensure that the working environment is 100% clean and sterile, these cylinders need to be maintained and replaced constantly, which can reduce the continuous precipitation and accumulation of residues. The cleaning and maintenance of standard cylinders takes a long time. Let us see what are the basic steps to design and produce this type of cylinder.

The problem that often occurs in this type of industry is the failure of equipment and systems, generally because the cylinder cannot achieve the performance required by the application. In fact, the application of the cylinder itself does not have too many defects, but it is more difficult to maintain and clean operations if it wants to run well during operation. Therefore, it is necessary to continuously update technology and increase productivity. In fact, the time required to clean a cylinder is not much, but usually a machine requires 8 cylinders to work at the same time, then time becomes a key factor to be considered. In addition to possible pollution, the deposits in the cylinder may further corrode the cylinder, thereby greatly reducing the service life of the cylinder.

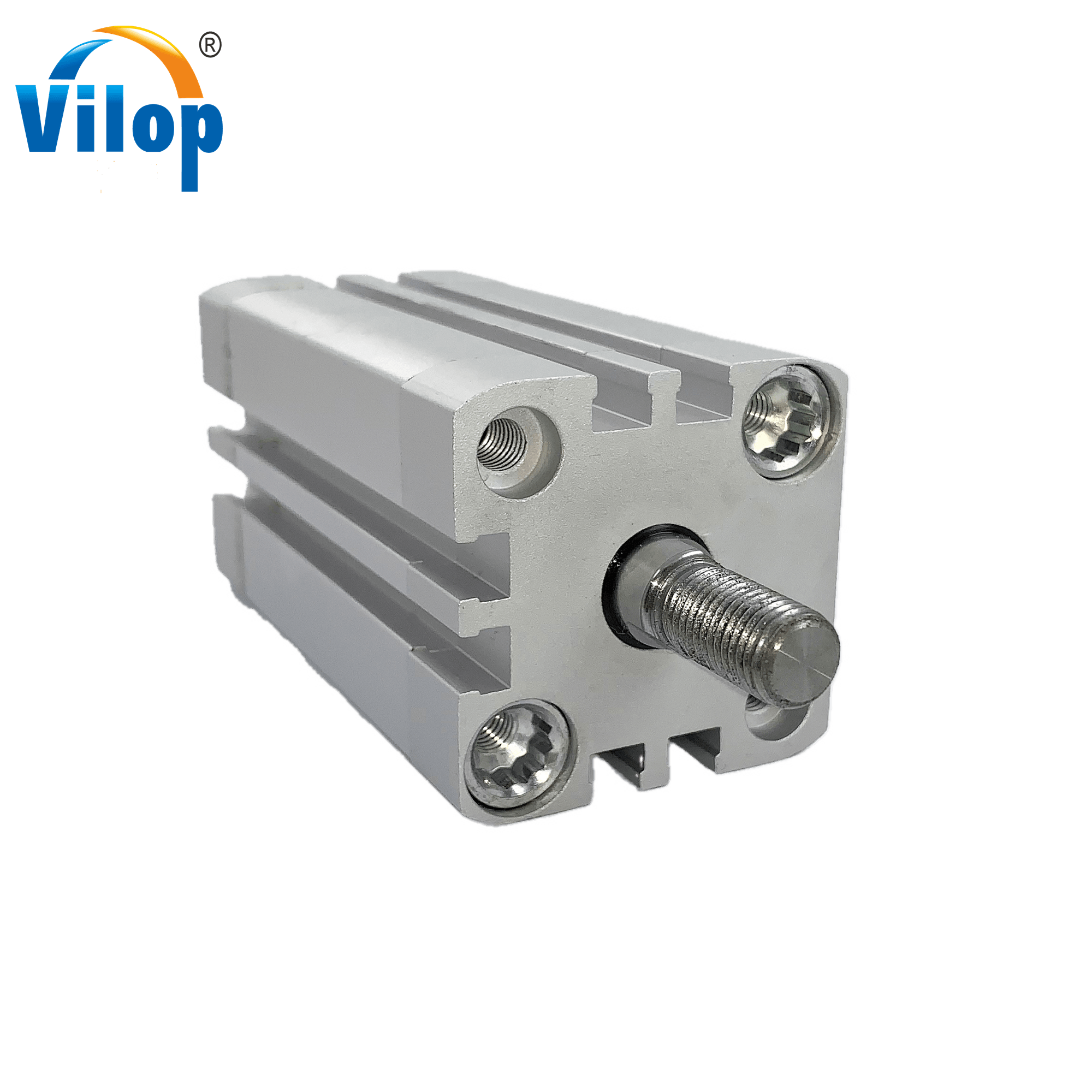

After considering the above factors, we developed a new type of cylinder that is easy to operate. Our design goal is to simplify repair time and minimize the use of parts that may cause residues from chemical agents. We chose to decompose the cylinder head into 2 small parts: the central one can be disassembled as a kind of cover, and by removing 4 easily accessible screws, the gasket can be removed and cleaned more quickly without wasting time. This method can reduce the maintenance time to one-tenth of the time previously required, and increase the frequency, thereby improving the performance of the machine and reducing the risk of contamination. Surprisingly, our technicians further removed the lever device, thereby improving the cleaning efficiency and almost eliminating the accumulation of residues.

Please call or use email to contact us for free consultation; we will be very happy to analyze your specific questions and guide you to choose the most suitable cylinder for you.